In the evolving landscape of manufacturing, CNC (Computer Numerical Control) machining and 3D printing have emerged as two pivotal technologies, each with distinct advantages and applications. Understanding their differences is crucial for industries and hobbyists alike, as the choice between CNC machining and 3D printing can significantly impact production efficiency, cost, and quality. This article delves into the core differences between these two manufacturing methods, exploring their unique characteristics, benefits, limitations, and typical applications.

CNC Machining: Precision and Versatility

CNC machining is a subtractive manufacturing process where material is removed from a large workpiece to create a desired shape. The CNC machine follows a programmed sequence of operations, which is meticulously designed using CAD (Computer-Aided Design) software.

Some CNC machining techniques include turning, milling, and drilling.

Key Characteristics of CNC Machining

1. Material Variety: CNC machining is compatible with a wide range of materials, including aluminium, copper, and plastic. This versatility makes it suitable for various industries, from aerospace to automotive to consumer goods.

2. Precision and Accuracy: CNC machines can achieve intricate designs and tight tolerances. This precision is essential for applications requiring high accuracy, such as aerospace components or medical devices.

3. Surface Finish: The surface finish of CNC-machined parts is generally superior to that of 3D-printed parts.

4. Scalability: CNC machining is highly scalable for both prototyping and mass production. Once a program is developed, it can be reused to produce large quantities of parts with consistent quality.

5. Speed: While setup and programming can be time-consuming, the actual machining process can be relatively fast, especially for large production runs.

Limitations of CNC Machining

1. Material Waste: As a subtractive process, CNC machining generates significant material waste, which can be costly, particularly with expensive materials like titanium.

2. Cost: CNC machines and their tooling can be more expensive than other methods.

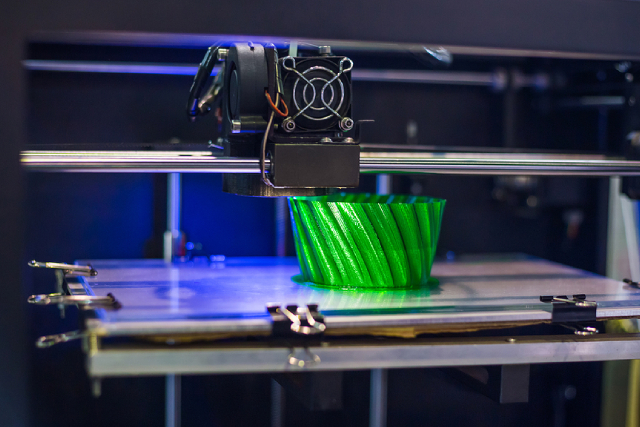

3D Printing: Innovation and Flexibility

3D printing, or additive manufacturing, creates objects layer by layer from digital models. This process involves adding material, such as plastic, resin, or metal powder, to build a part from the ground up. Various 3D printing technologies exist, including SLA (Stereolithography), SLS (Selective Laser Sintering), and DMLS (Direct Metal Laser Sintering).

Key Characteristics of 3D Printing

1. Design Freedom: 3D printing allows for the creation of intricate designs and complex geometries that would be challenging to achieve with conventional manufacturing methods. This capability is particularly valuable for producing customised or unique parts.

2. Material Efficiency: As an additive process, 3D printing generates minimal waste. Material is only used where needed, making it a more sustainable option compared to subtractive processes.

3. Rapid Prototyping: 3D printing excels in rapid prototyping, enabling designers and engineers to quickly produce and test multiple iterations of a part. This accelerates the development cycle and reduces time-to-market.

4. Accessibility: Desktop 3D printers are relatively affordable, making the technology accessible to hobbyists, educational institutions, and small businesses.

5. Customisation: 3D printing is ideal for producing customised or one-off parts, such as medical implants, dental devices, or bespoke consumer products.

Limitations of 3D Printing

1. Material Limitations: While the range of 3D printable materials is expanding, it is still limited compared to CNC machining. Certain high-performance materials used in CNC machining are not yet available for 3D printing.

2. Post-Processing: Many 3D printed parts require significant post-processing, such as cleaning up, to achieve the desired surface finish and mechanical properties.

Comparing CNC Machining and 3D Printing

1. Cost Considerations

- Initial Investment: CNC machines typically require a higher initial investment than 3D printers. However, for high-volume production, CNC machining can be more cost-effective due to economies of scale.

- Material Costs: Material costs for CNC machining can be higher due to waste, whereas 3D printing materials are used more efficiently.

- Operational Costs: CNC machining often incurs higher operational costs due to tooling, maintenance, and skilled labour. In contrast, 3D printing operations can be more automated and less labour-intensive.

2. Production Speed

- Prototyping: 3D printing is generally faster for prototyping due to its ability to quickly produce and iterate designs without the need for complex setup or tooling.

- Mass Production: CNC machining is better suited for mass production, offering faster production rates and consistent quality for large quantities of parts.

Part Complexity

- Simple Parts: For simple, high-precision parts, CNC machining is often the preferred choice due to its accuracy and surface finish.

- Complex Parts: 3D printing excels in producing complex and intricate parts without the need for additional tooling or setup.

Conclusion

CNC machining and 3D printing are transformative technologies that cater to different manufacturing needs. CNC machining offers unmatched precision, material versatility, and scalability, making it ideal for high-precision and high-volume production. In contrast, 3D printing provides unparalleled design freedom, rapid prototyping capabilities, and material efficiency, which are essential for producing complex, customised, and low-volume parts.

Choosing between CNC machining and 3D printing depends on various factors, including the specific requirements of the part, the production volume, material considerations, and cost constraints. By understanding the strengths and limitations of each technology, manufacturers can make informed decisions to optimise their production processes and achieve the best possible outcomes for their projects.

For 3D printing and CNC machining services, reach out to us at Monster Builder. We also offer sheet metal fabrication services at competitive prices. Reach out to us for more information.