When it comes to manufacturing and precision engineering, the choice between CNC (Computer Numerical Control) machining and conventional machining is a critical decision that can significantly impact the outcome of a project.

Both methods have their merits and applications, but understanding their differences and respective advantages is essential for making an informed decision. In this article, we’ll explore the nuances of CNC and conventional machining, examining their strengths, limitations, and when it’s appropriate to opt for each.

Understanding CNC Machining

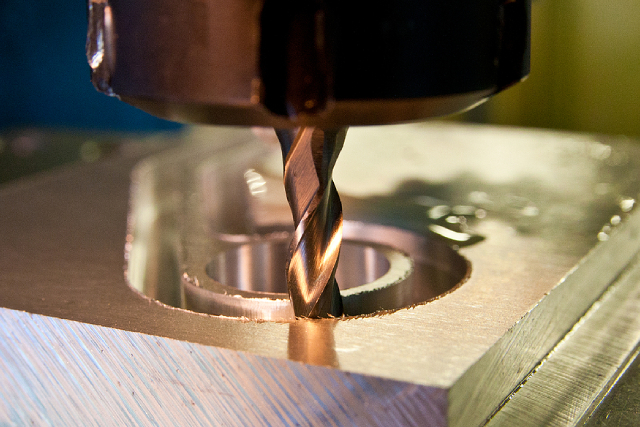

CNC machining is a highly automated manufacturing process that utilizes computer-controlled machinery to cut and shape materials into finished parts or components precisely. Unlike conventional machining, which relies on manual operation and human intervention, CNC machining is driven by programmed instructions (G-code) that dictate the movement and operation of the machine tools. Here’s a closer look at the key features of CNC machining.

- Automation: One of the primary advantages of CNC machining is its automation capabilities. Once the machining program is set up and the machine is calibrated, it can operate autonomously, executing complex machining operations with high accuracy and repeatability.

- Precision: CNC machines are capable of achieving extremely tight tolerances and intricate geometries with consistency and reliability. The precision of CNC machining makes it ideal for producing complex parts that require precise dimensions and surface finishes.

- Versatility: CNC machining is compatible with a wide range of materials, including metals, plastics, and composites. It can accommodate various machining operations, such as milling, turning, drilling, and grinding, allowing for versatile manufacturing capabilities.

- Flexibility: With CNC machining, it’s relatively easy to make adjustments to the machining program or switch between different parts or setups. This flexibility enables rapid prototyping, short production runs, and efficient production scheduling.

Exploring Conventional Machining

Conventional machining, also known as manual machining or traditional machining, relies on manual control and operator expertise to perform cutting, shaping, and finishing operations on raw materials. While it lacks the automation and precision of CNC machining, conventional machining still holds relevance in certain applications. Here are some key aspects of conventional machining:

- Operator Skill: Conventional machining requires skilled operators who have a deep understanding of machining principles, tooling selection, and machine operation. The operator’s expertise plays a crucial role in achieving accurate results and optimizing machining parameters.

- Customization: Conventional machining offers a high degree of customization and adaptability, as operators have greater control over the machining process. They can adapt to observations and unforeseen circumstances, making real-time adjustments to cutting speeds, feed rates, and tool paths to optimize performance and achieve desired outcomes.

- Low Initial Investment: Compared to CNC machining, conventional machining equipment tends to have a lower upfront cost, making it more accessible to small businesses and workshops with budget constraints. Additionally, maintenance and repair costs may be lower for conventional machines.

- Suitability for Simple Parts: Conventional machining is well-suited for producing simple parts or components that do not require intricate geometries or tight tolerances. It can be particularly effective for jobs that involve basic shaping, drilling, or turning operations.

Choosing Between CNC and Conventional Machining

So, how do you decide whether to opt for CNC machining or conventional machining for your project? Here are some factors to consider:

- Complexity and Precision: If your project involves intricate designs, tight tolerances, or complex geometries, CNC machining is likely the better choice due to its automation and precision capabilities. CNC machines excel at producing parts with consistent quality and high accuracy.

- Volume and Production Run: For small to medium production runs or prototyping, CNC machining offers greater efficiency and repeatability compared to conventional machining. However, for one-off or custom jobs, conventional machining may be more cost-effective, especially if tooling costs are a concern.

- Material and Machining Operations: Consider the type of material you’re working with and the specific machining operations required. CNC machining is versatile and can handle a wide range of materials and processes, while conventional machining may be better suited for certain materials or simpler operations.

Conclusion

The choice between CNC machining and conventional machining depends on various factors, including the project’s complexity, required precision, production volume, and material considerations. Ultimately, the decision should be based on a thorough evaluation of your project requirements, budget constraints, and machining capabilities. By carefully weighing the pros and cons of each method, you can make an informed decision that maximizes efficiency, quality, and cost-effectiveness for your manufacturing needs.

If you’re looking for CNC machining services in Singapore, reach out to us at Monster Builder. A leading metal fabrication and machining company, we also offer sheet metal fabrication, 3D printing, and more.