In manufacturing, the choice of fabrication method can significantly impact a business’s bottom line, production efficiency, and product quality.

Sheet metal fabrication stands out as a versatile and cost-effective solution for businesses across various industries. This article explores the myriad benefits of sheet metal fabrication and why businesses should consider it as their preferred manufacturing method.

Understanding Sheet Metal Fabrication

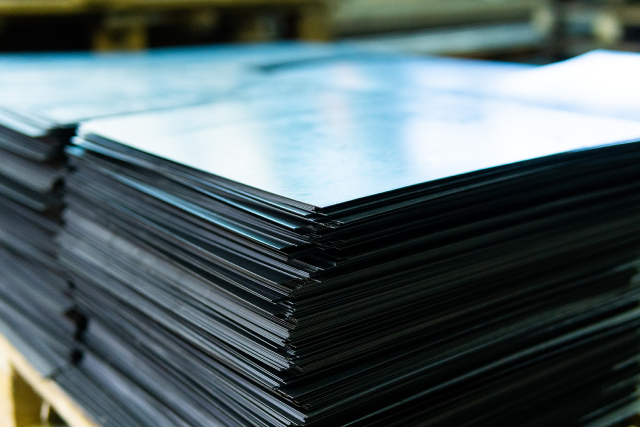

Sheet metal fabrication is a manufacturing process that involvesthin metal sheets being shaped and formed into finished components or products. It encompasses a range of techniques, including cutting, bending, punching, welding, and assembly, to transform flat sheets of metal into intricate and precise parts. Common materials used in sheet metal fabrication include steel, aluminium, stainless steel, and copper, among others.

Key Advantages of Sheet Metal Fabrication

1. Versatility and Customization

Sheet metal fabrication is popularly used due to its versatility and ability to accommodate various designs and specifications. Whether it’s simple brackets or complex enclosures, sheet metal can be shaped and manipulated to meet the unique requirements of each project.

Businesses can leverage sheet metal fabrication to create custom parts and components tailored to their specific applications, allowing for greater flexibility in product design and functionality.

2. Cost-Effectiveness

Sheet metal fabrication offers cost-effective solutions for manufacturing both low-volume and high-volume production runs. The relatively low cost of raw materials results in competitive pricing for finished products.

Moreover, the manufacturing process is highly efficient, maximizing available materials and minimizing waste, resulting in lower costs. The automated machinery and computer-aided design (CAD) software also help streamline the process, reducing production costs.

3. Rapid Prototyping and Iteration

For businesses involved in product development and prototyping, sheet metal fabrication provides a quick and efficient means of testing designs and iterating on concepts. Rapid prototyping allows for faster validation of ideas, leading to accelerated time-to-market and reduced development costs.

With advancements in CAD software and simulation tools, designers can create virtual prototypes and simulate manufacturing processes, minimizing the need for physical prototypes and speeding up the design iteration cycle.

4. Strength and Durability

Despite its thin profile, sheet metal exhibits high strength and durability, making it suitable for a wide range of applications across industries. Whether it’s structural components in construction or enclosures in electronics, sheet metal offers superior mechanical properties and longevity.

Through various forming and finishing techniques, sheet metal parts can be further enhanced to withstand harsh environments, corrosion, and wear, ensuring long-term performance and reliability.

5. Scalability and Mass Production

Sheet metal fabrication is highly scalable, making it ideal for both small-batch production and large-scale manufacturing operations. With automated equipment and efficient workflow processes, businesses can seamlessly transition from prototyping to mass production without compromising quality or efficiency.

The ability to replicate complex geometries and features consistently ensures uniformity across production batches, maintaining product quality and meeting market demand.

Applications Across Industries

1. Automotive and Aerospace

In the automotive and aerospace industries, sheet metal fabrication is used to manufacture chassis components, body panels, aircraft structures, and interior fixtures. Its lightweight yet robust properties make it well-suited for enhancing fuel efficiency and optimizing vehicle performance

2. Electronics and Telecommunications

Sheet metal fabrication plays a crucial role in the production of electronic enclosures, racks, and cabinets for housing sensitive electronic components and telecommunications equipment.

3. Construction and Architecture

In construction and architecture, sheet metal fabrication is employed to fabricate structural elements, roofing materials, façades, and decorative features. Its malleability and aesthetic appeal allow for the creation of visually stunning and functional designs in both residential and commercial projects.

4. Medical and Healthcare

The medical and healthcare sectors utilize sheet metal fabrication for manufacturing medical devices, equipment enclosures, instrument trays, and surgical fixtures. Its sterile properties, corrosion resistance, and ease of sterilization make it a preferred material for critical healthcare applications.

Conclusion

Sheet metal fabrication offers a myriad of benefits for businesses seeking efficient, cost-effective, and customizable manufacturing solutions. From rapid prototyping to mass production, its versatility and versatility make it indispensable across industries ranging from automotive and aerospace to electronics and healthcare. By leveraging the strengths of sheet metal fabrication, businesses can streamline their production processes, enhance product quality, and gain a competitive edge in today’s dynamic marketplace.

As a leading metal fabrication and machining company in Singapore, Monster Builder offers a range of services, including sheet metal fabrication, 3D printing, and CNC machining. Reach out to us to find out more.